Making sodium silicate by hot process (and anticaking agent)

preparing sand

If you have access to silica based cat litter use it as it's very porous and pure silicon dioxide, but if you do it's better to dissolve it in aqueous solution of sodium hydroxide rather than using this process.

My sand is very low quality as it has a lot of rubble in it e.g. small pieces of bricks. Beach sand works best so use it if you can.

Sand has been collected into a bucket.

Then it was washed around 7 times in water to get rid of organic contaminants and dust.

After washing in water it was covered in dilute sulfuric acid (around 3%) for 5 hours being stirred occasionally. This dissolves any other oxides like CaCO3 and AlO3.

Acid was decanted into bottle for later use, after settling the solution had yellow tinge.

And again sand was washed with water.

For this process sand has to be dry. It can be put into a cloth for faster drying, and then spread to dry in sun. I've chosen to dump it into a pot and heat it to dryness.

Resulting sand was put into a bottle

mixture

Sodium silicate can refer to many compounds

2NaOH + SiO2 -> H2O + Na2SiO3 sodium metasilicate

4NaOH + SiO2 -> 2H2O Na4SiO4 sodium orthosilicate

2NaOH + 2SiO2 -> H2O + Na2Si2O5 sodium silicate

To make Na2SiO3 2 moles of sodium hydroxide and one of silicon dioxide is required giving the ratio of 4 : 3 by weight.

Sodium silicate (water glass) cannot be made in this process. Molten sodium hydroxide reacts with silicon dioxide forming sodium silicates which cannot react further with silicon dioxide unless they are dissolved in water, the solid form of a powder has too small of a contact area.

I've used ratio of 3 sodium hydroxide to 5 of silicon dioxide. For this process having excess sand ensures that no hydroxide will be left, but as stated above a lot of sand is left unreacted.

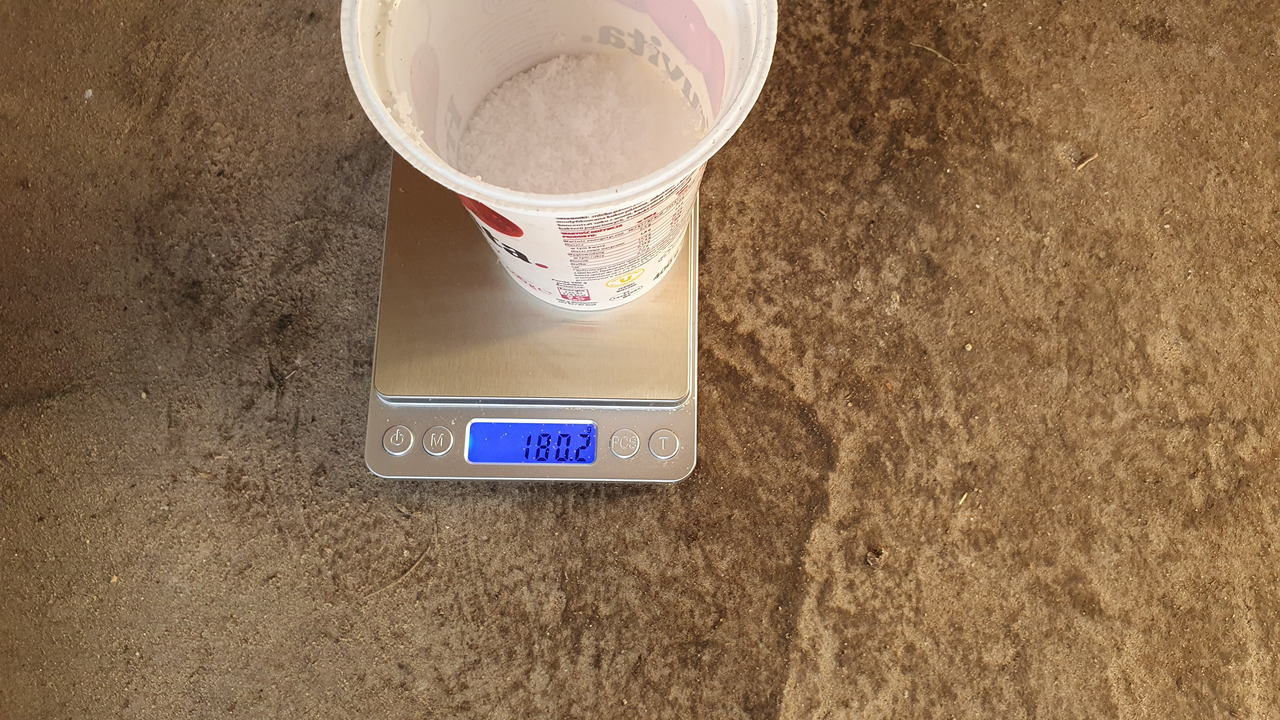

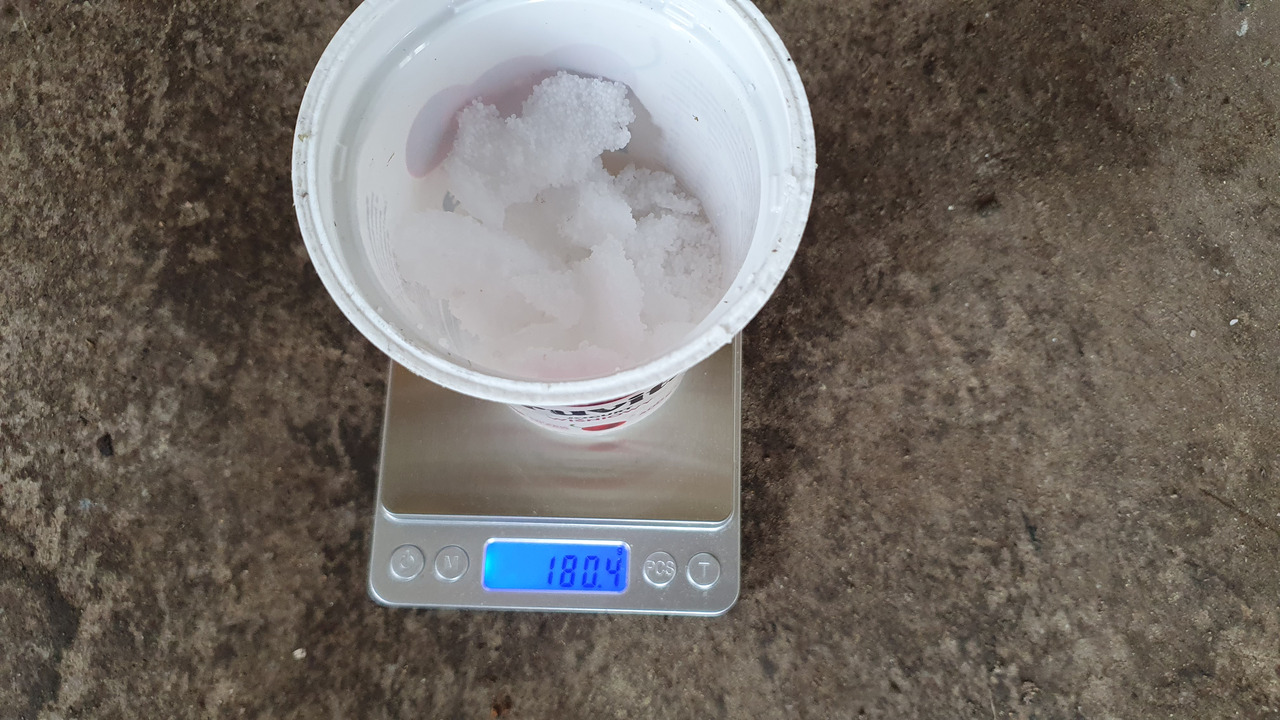

I've prepared 300g of silicon dioxide, and 180g of sodium hydroxide.

reaction

This reaction takes place only when sodium hydroxide is molten (above 310C). You can also use sodium carbonate instead of hydroxide but it has melting point of 851C (cherry red incandescence) which is quite hard to achieve unless you put it into the centre of a furnace.

failed attempt

Reactants were placed into a pan and mixed

Pan was placed on a rocket stove. When top of the mixture reached 150C without stirring it became white, "wet" and lumpy.

Mixture was mixed and became a white fluffy powder at around 290C (measured from the top), some hard lumps have formed but more heat did not break them.

Sodium metasilicate has solubility of 22.2g/100ml at 20C and 160.6g/100ml at 80C in water so its much easier to dissolve when hot. After it cooled down i've poured in water to dissolve the product and put it back on the stove.

The solution started to bubble excessively

And it quickly became a sludge. I've discovered that my pan was made of aluminium and while it was resistant to molten sodium hydroxide it reacted with aqueous sodium silicate the same way as it does with aqueous sodium hydroxide. I've transferred it to my steel pot to find a shiny aluminium surface on the pan.

After a night it had taken a little of a iron coloring

I've blasted it to dryness and crushed it with a crowbar only to find that the bottom of it got some nice pale blue color (even nicer than in the picture) and i'm pretty sure there were no copper contaminants in the pot.

I've run it through my pipe mortar and the powder weighted 414.9g and was quite dense

This experiment scarred my pot with not easy to dissolve rock coating

And so sodium aluminosilicate has been made. Apparently it's used as anticaking agent in food (E 554) and as molecular sieves for medicinal containers.

second attempt

The same reagents in the same amounts were prepared.

![]()

As you might've noticed sodium hydroxide is quite chunky, and that's because i forgot to close the container when taking it for the first attempt so it was open for 2 days. Fortunately it did not turn into a but it had formed a hard layer on top and after little bit of excavating i've uncovered a fine piece.

After placing everything to a pot again, i grinded the hydroxide chunks with sand using a thick stick which was surprisingly easy, chunks easily crumbled.

And again mixture was blasted on rocket stove and went from yellow powder to clumpy white powder to white fluffy powder with chunks.

Looking at this powder i've had a revelation and poured in 400ml of cold water into 330C powder. This caused an explosion and i was fortunate enough to not be affected. After it settled i've poured in another 400ml of water and boiled it trying to dissolve the product.

As you can see solution has a brown reddish tinge, this is caused by it dissolving any iron oxides in the pot. If you want a clear solution transfer the powder to glassware and dissolve it there.

Sodium silicate behaves similarly to sodium hydroxide. It has pH of about 12.5, is able to dissolve metal oxides and slightly oxidize metals, reacts with aluminium and destroys PET plastic faster then NaOH and even concentrated KOH (my bottle was leaking after 1 hour). The only dissimilarity i've found was that it doesn't dissolve sulfur like sodium hydroxide solution after heating would so you can use it as an indicator of its presence.

As seen on the second picture sodium silicate started crystallising above the water level so i've been adding water while keeping it boiling until it stopped.

The solution is quite muddy because water level in pot is quite low. The same solution in taller container after settling is clear although colored.

Everything was poured off into my 5L HDPE container

Later i've dried the leftover sand and weighted it, it was around 130g which is close to what ideally would not get reacted (135g) if only sodium metasilicate was made. After a couple of days it developed a sand crust on top meaning that some sodium silicate was left also confirming that it works.

notes about purification

Sodium silicate is a paper glue! If you attempt to use paper filter on it, it'll slowly drip for 10 minutes and then completely clog.

The Canadian Chemist made a video about this process and used 95% ethanol to separate it from leftover sodium hydroxide since hydroxide has high solubility in it, although i doubt it was there since sodium silicates readily bind with excess sodium hydroxide to form sodium silicates with more sodium. I've tried this method but i've used low quality ethanol (gel fuel) which had more water, as it was dissolving it heated to the point of boiling and formed the hardest rock i've ever come by. Sodium silicate reacts with ethanol and water to produce some kind of a silicone that in my case binded with sodium silicate itself.

testing

I've attempted to use it as a paper glue and because it was so dilute it took a long time for it to set.

I've tried recreating the chemical garden experiment but things grew only a little, nothing impressive.

The best use for it is to make rock hard sand castles.